Well controlled laser beam hazards are critical. In addition to laser beam hazards, laser non-beam hazards must be considered.

- Mechanical Hazards

- Electrical Hazards

- Smoke and Fumes

- Process Radiation

Let’s take a brief look at each of these laser non-beam hazards.

Mechanical Hazards

Mechanical hazards are common in industrial laser areas. Industrial laser personnel must often deal with heavy or sharp objects, parts handlers or robots. Failure to operate these systems properly can result in serious injury.

Electrical Hazards

Most laser power supplies contain severe electrical hazards. They often contain high voltages, energy storage capacitors and possibly water cooling. There have been several fatalities when workers did not follow appropriate electrical hazard procedures. The type of laser that has produced the greatest number of electrocutions is the industrial CO2 laser. Electrocutions have also occurred with Nd:YAG, Ruby, Argon, and Excimer lasers. Only qualified personnel should work with energized power supplies. Follow lock-out procedures as required.

Smoke and Fumes

Laser cutting, welding, or other materials processing applications create laser generated air contaminants. Most of the material vaporized by lasers during metal processing generates particles less than a micron in size. These particles are a respiratory hazard. Processing non-metals usually produces hazardous chemical vapors. Vaporizing wood produces large quantities of benzene. Vaporizing plastics can produce many carcinogens. Remove LGACs with appropriate filters or exhaust systems.

Process Radiation

Laser welding often produces process radiation. Some of the metal is vaporized, resulting in the metal vapor rising into the beam path. Some of the laser light is absorbed by the metal vapor, heating it to very high temperature. It glows like an electrical arc which products a lot of blue light. Blue light can cause a burn on your retina which is similar to a sunburn on your skin. Use a protective filter or eyewear to view blue or white light sources comfortably. Eyewear that blocks the laser light as well as the blue light may be available.

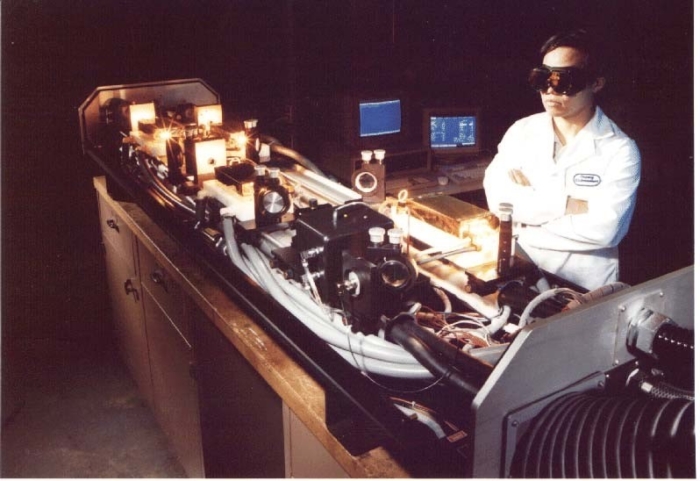

Laser non-beam hazards present in this photo include scattered laser light, ultraviolet radiation, blue light, and laser generated air contaminants.

The intense light from laser optical excitation sources produces a white light optical hazard. Use eyewear to protect against this laser non-beam hazard.

Kentek’s online laser safety training and LSO training courses cover laser non-beam hazards in depth. As always please don’t hesitate to reach out with comments/questions – 603-223-4900 or rgreene@kenteklaserstore.com.