Working for the world’s leading laser safety company we come across lots of laser eye protection questions. This brief post will address some common and general items but always check with your LSO for your specific requirements. ANSI Z136.1 requires laser eye protection for Class 3B and 4 lasers or laser systems within the Nominal Hazard Zone (NHZ) when engineering or procedural controls are not practicable. For those of you requiring laser eye protection, here are some things you should consider.

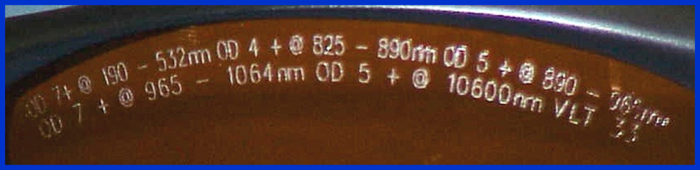

- Make sure your laser eye protection is marked for the appropriate wavelength(s) and optical density . The ANSI Z136.1 standard requires all laser protective eyewear shall be clearly labeled with the optical density and wavelength for which protection is afforded – section 4.4.4.2.6.

- There are many factors to consider when selecting laser eye protection. Below is a list straight from ANSI Z136.1 – section 4.4.4.2.2:

- Laser power and/or energy

- Wavelength(s) of laser output

- Potential for multi-wavelength operation

- Radiant exposure or irradiance levels for which protection (worst case) is required

- Exposure time criteria

- Maximum Permissible Exposure (MPE)

- Optical density requirement of eyewear filter at laser output wavelength

- Angular dependence of protection afforded

- Visible light transmission requirement and assessment of the effect of the eyewear on the ability to perform tasks while wearing the eyewear

- Need for side-shield protection and maximum peripheral vision requirement

- Radiant exposure or irradiance and the corresponding time factors at which laser safety filter characteristics change occurs, including transient bleaching especially for ultrashort pulse lengths,

- Need for prescription glasses

- Comfort and fit

- Degradation of absorbing media, such as photobleaching

- Strength of materials (resistance to mechanical trauma and shock)

- Capability of the front surface to produce a specular reflection

- Requirement for anti-fogging design or coatings

- Frequent inspection of laser eye protection is also important. Both the lens and the frame should be considered.

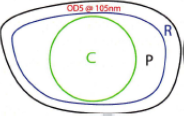

Central (C) = 28mm Optical Center or apex of the lens, Peripheral (P) = Remaining area outside the optical center, Rim (R) = 3mm perimeter of the lens. Below is a chart to help with this process.

| White Marks (discoloration) | P-None | C-None | R-None |

| Blemishes | P<0.5mm | C-None | R-Acceptable |

| Swirls | P-None | C-None | R-Acceptable |

| Pits, Digs | P<4mm | C-None | R-Acceptable |

| Surface Scratches | P<0.011(w)x3(l) | C-None | R<0.011(w)x6(l) |

| Coating Tack | P-None | C-None | R-None |

When inspecting the frame look for broken or cracked areas. If the frame has adjustable temples or ratcheting arms make sure they are functional. Last but not least proper fit and comfort is key. If laser eye protection doesn’t fit properly or is uncomfortable it is more likely it won’t be worn.